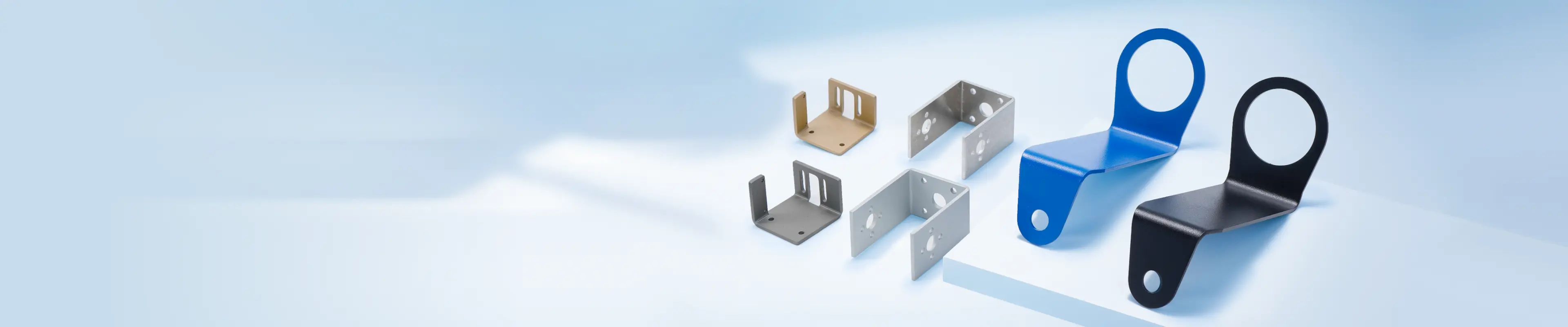

Sheet Metal Fabrication Services

Sheet Metal Cutting

Laser Cutting, CNC turret, punching of various sheet metal materials.

Sheet Metal Forming

Right-angle bending, radius bending, U-shape, V-shape or step bending, and hemming.

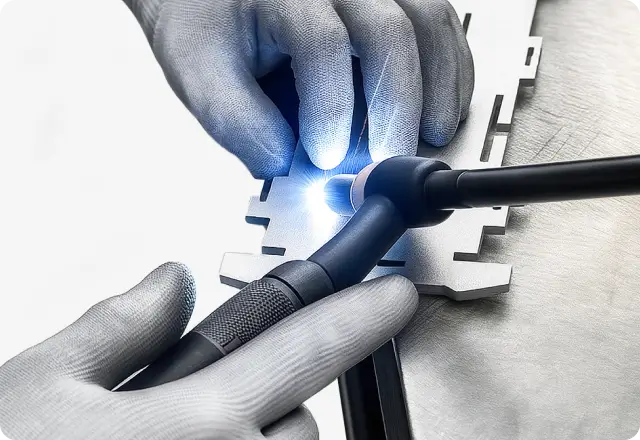

Sheet Metal Assembly

Laser welding, MAG welding, TIG welding. Riveting, and fastening.

Sheet Metal Finishing

Various surface finishing options: anodizing, powder coating, brushing, etc.

Sheet Metal Capabilities

Sheet Metal Materials

Aluminum 5052

Characteristic: Aluminum 5052 offers excellent corrosion resistance and formability. With more magnesium than 6061, it’s easy to weld and machine, making it great for marine and chemical applications.

Lead Time: As fast as 1 day

Finishing Options: Anodizing, Hardcoat Anodizing, Powder Coating, Silkscreen, Laser marking. Learn more >

Stainless Steel 201

Characteristic: Stainless steel 201 offers moderate resistance to acids and alkalis, features high density, and exhibits excellent surface finish with no visible porosity or pinholes after polishing.

Lead Time: As fast as 1 day

Finishing Options: Brushing, Powder Coating, Silkscreen, Laser marking. Learn more >

Stainless Steel 304

Characteristic: Stainless steel 304 offers high temperature resistance up to 800°C, good processing performance, and high toughness.

Lead Time: As fast as 1 day

Finishing Options: Brushing, Powder Coating, Silkscreen, Laser marking. Learn more >

Cold Rolled Steel

Characteristic: Cold Rolled Steel offers high-precision dimensions, excellent surface smoothness, and superior deep-drawing capabilities while requiring protective coatings against oxidation due to its unprotected surface.

Lead Time: As fast as 1 day

Finishing Options: Powder Coating, Silkscreen, Laser marking. Learn more >

Galvanized Steel Sheet

Characteristic: Galvanized steel sheet offers excellent corrosion resistance and decorative appearance while maintaining the workability of cold-rolled steel, featuring a thicker zinc coating than electro-galvanized alternatives, though with reduced weldability and formability, making it ideal for construction, appliances, and automotive applications where durability outweighs deep-drawing needs.

Lead Time: As fast as 1 day

Finishing Options: Powder Coating, Silkscreen, Laser marking. Learn more >

- Aluminum 5052 • <

Aluminum

- Stainless Steel 201 • <

- Stainless Steel 304 • <

Stainless Steel

- Cold Rolled Steel • <

- Galvanized Steel Sheet • <

Steel Alloy

Sheet Metal Surface Finishes

Standard

Parts are machined and deburred with no additional surface finish. Visible machining marks, light surface scratches.Anodizing

Anodizing creates a corrosion-resistant, uniform, matte or glossy finish. Parts can be anodized in different colors—black, red, and gold are most common.Hardcoat Anodizing

A type of anodizing that produces a thicker and harder coating on the surface, resulting in increased wear resistance and durability.Conductive Anodizing

An anodizing process that creates a conductive oxide layer on the surface, typically used for EMl/RFl shielding or electrical grounding applications.Powder Coating

Electrostatic dry powder application cured under heat. Eco-friendly, durable finish with superior corrosion resistance for metal parts.Brushing

Parts are brushed using an abrasive tool to create a pattern of fine parallel lines on the material surface, producing a unique aesthetic effect.Silkscreen

A part marking technique that uses a fine mesh screen to apply ink onto a surface, to print the desired text or image onto the substrate.Laser Marking

Laser marking uses a laser beam to create permanent marks or designs on the surface of a material, typically resulting in high precision and resolution.